Sponsored by CavitarReviewed by Louis CastelSep 30 2022

In recent years, an abundance of new arc welding processes has infiltrated the international welding scenario in the industry and academia. Such progress has been made possible through new electronics and advanced software developments, and the introduction of new concepts in mechanical design and mechanisms.

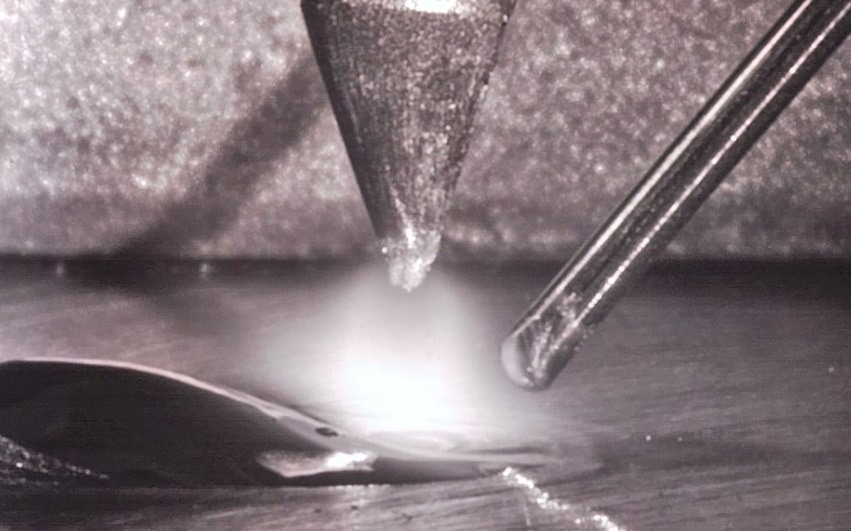

Image Credit: Cavitar

With respect to the TIG process, one such instance is Dynamic Feed (Wire Oscillation). Low productivity is typically one drawback associated with traditional TIG, in contrast to other arc welding processes.

For the purpose of managing this drawback, as well as to better handle hard wetting materials (Ni-Cr alloys, for instance), a forward and backward wire oscillation movement has been introduced in TIG systems. This has been well received throughout the industry and attracted significant interest within the scientific community.

Additionally, another advantage to expect from the new technique is reduced porosity. For the study and development of such methods, high-speed imaging has been a useful tool for observing and assessing the stability of the metal fusion and transfer, arc behavior, and weld pool behavior.

The primary objectives of the scientific investigations are the influence of parameters over the resulting physical phenomena and the development of parameterization under various welding conditions (position of torch geometry, wire dynamics, and wire feeding).

Visualization of TIG Welding with CAVILUX Laser Illumination

Video 1. Dynamic Feed TIG Welding imaged at 1.000 fps. Video Credit: Cavitar

With respect to MIG/MAG welding, new technologies are aimed at further advancing adaptive control methods, state-of-the-art current waveforms and mechanization techniques in order to enhance arc stability, metal transfer regularity, process reliability and expansion of the application range.

Here, the rotary arc and the pulsed arc mode are offered as examples, which show great potential for acquiring exceptional results for cladding and thick-walled narrow gap joints. In such cases, high-speed imaging is used for observations of metal transfer phenomena, arc movement patterns, and respective influences over the weld pool, arc geometry and generation of the weld bead.

Moreover, high-speed imaging techniques have been applied during the evaluation of consumables and peripherals (such as wire-electrodes, contact tips and wire feeders).

Visualization of Arc Creation in GMAW with CAVILUX Illumination Laser

Video 2. Rotary Arc Pulsed MIG/MAG Welding imaged at 5.000 fps. Video Credit: Cavitar

Research on Modern Variants on Classical Arc Welding with CAVILUX Illumination Laser

Video 3. MIG/MAG Welding with forward/backward movement of the wire electrode imaged at 4.166 fps. Video Credit: Cavitar

For the videos presented in this article, a CMOS, 1.0-megapixel array size camera was utilized with 105 mm and 180 mm macro lenses. Acquisition rates were modified in parallel with electric welding data monitoring via a Data Acquisition System.

Throughout these investigations and developments, CAVILUX HF has been used on an extensive basis. The laser illumination system allows the arc intensity of the high-speed images produced to be finely adjusted, thus enabling the selection and isolation of specific welding process features (wire, arc, droplet, pool, etc.), which objectives state should be specifically monitored, analyzed, and investigated.

This information has been sourced, reviewed and adapted from materials provided by Cavitar.

For more information on this source, please visit Cavitar.