Dec 10 2018

An artificial soft skin imbued with flexible electronics could improve the way robots sense and interact with their environs, KAUST scientists have demonstrated. The scientists have discovered a way to program electrical conductivity and strain sensing into a single material fixed in a stretchy polymer skin. The discovery could also be used in wearable electronic devices.

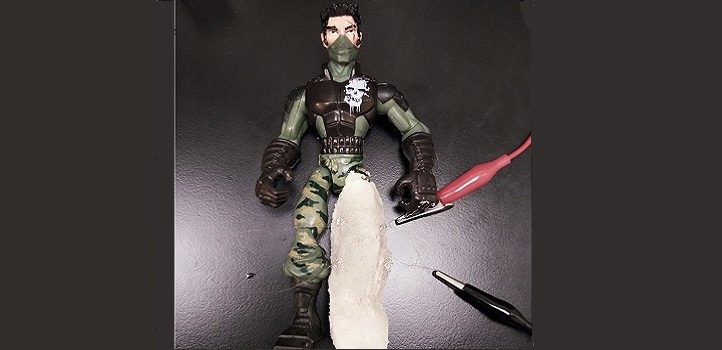

The leg of the action figure was coated in a strain-sensing artificial skin to demonstrate the material in action. (Reproduced with permission from reference 1 © 2018 Wiley-VCH)

The leg of the action figure was coated in a strain-sensing artificial skin to demonstrate the material in action. (Reproduced with permission from reference 1 © 2018 Wiley-VCH)

When an animal extends a limb, a network of sensors and nerves within the skin delivers feedback that helps it orient the limb in space and interact with its environment. Implanting a network of strain sensors and connective wiring into a flexible artificial skin would offer soft robots similar sensory feedback, helping them independently steer through their environment, says Gilles Lubineau, who led the study.

Until recently, scientists have used various materials for the sensing and conductive wiring components, adding complexity and cost to the fabrication process, explains Ragesh Chellattoan, a Ph.D. student in Lubineau’s team.

Our objective is to get both sensing and wiring connectivity in the one material.

Ragesh Chellattoan, Ph.D. Student, KAUST.

The team created an artificial material made up of a flexible polymer embedded with silver nanowires. Independently, each nanowire is conductive, but high resistance at the junctions between them restricts overall conductivity through the material. The resistance increases significantly when the material is flexed and the nanowires are pulled apart such that the nanowire network serves like a strain sensor.

But that behavior can be changed, the team demonstrated. Applying a DC voltage made the nanowire network extremely hot at the points of high resistance, where the nanowires meet. This localized heating serves to weld adjacent nanowires together, developing a highly conductive firmly bonded network that is impermeable to stretching and flexing.

Electrical welding joins thousands of junctions in the network within 30 seconds.

Ragesh Chellattoan, Ph.D. Student, KAUST.

Altering how the current is introduced regulates which parts turn conductive.

The team developed a stretchy skin for a toy action figure to showcase their material. They coated one of the figure’s legs with the artificial skin and then applied DC voltage only to the leg’s left side before flexing the leg at the knee and noting what took place. On the right side, the nanowire network behaved as a strain sensor that could sense the leg position as the figure’s knee was bent and straightened; the left side exhibited high conductivity irrespective of leg position.

The following step, Chellattoan says, is to gain better control over where nanowire welds form. This would provide scientists the ability to form precise conductive patterns into the artificial skin.