Showa Denko has developed an artificial intelligence-based image analysis system for spherical alumina production in cooperation with BLUE TAG. SDK will start using the system at its production line in April this year.

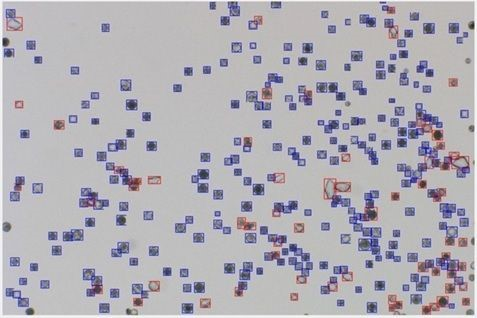

A picture under the image-analysis system

A picture under the image-analysis system

Spherical alumina is produced from molten material, using surface tension. The product is in the form of particles with diameters ranging from several microns to 70 um. Due to high fluidity and compatibility, it is used as filler for heatsinks for electronic components and as abrasive. In the production process, operators visually inspect the product using optical microscopes to see if there is a defect in sphericity. Production conditions are adjusted through feedback of the inspection information to the preceding process. As there are many types of defective shapes, operators make a judgement on particle conditions based on their own experience. Furthermore, it is difficult to quantitatively grasp particle conditions, resulting in difficulty in using relevant information for the purpose of productivity improvement and quality stabilization.

SDK has therefore developed the AI-based image analysis system to visualize experience-based knowledge of skilled operators. This was not possible under the conventional image-analysis software. The new system is also aimed at ensuring quick feedback of digitalized data to the production process to stabilize product quality. To use examples of skilled operators' judgement as training data, SDK utilized BLUE TAG's high technology of micro-level-image processing.

As a result of initial tests, we confirmed the system's ability to make a judgment at the same level as that of skilled operators in about 20 seconds. This system also enables accumulation of data for relearning processes. Thus, inspection accuracy under the system can be improved based on operation results at the production line. SDK's spherical alumina product has the advantage of uniformity in sphericity and stability in product quality. Fully utilizing the new AI-based image analysis system, we will work to further improve product quality and productivity.

The Showa Denko Group is promoting AI and IoT technologies under its medium-term business plan "The TOP 2021." SDK will continue utilizing these technologies at production sites to visualize and quantify technology and experience-based knowledge possessed by experts, thereby ensuring safe and stable operation and strengthening competitive power.