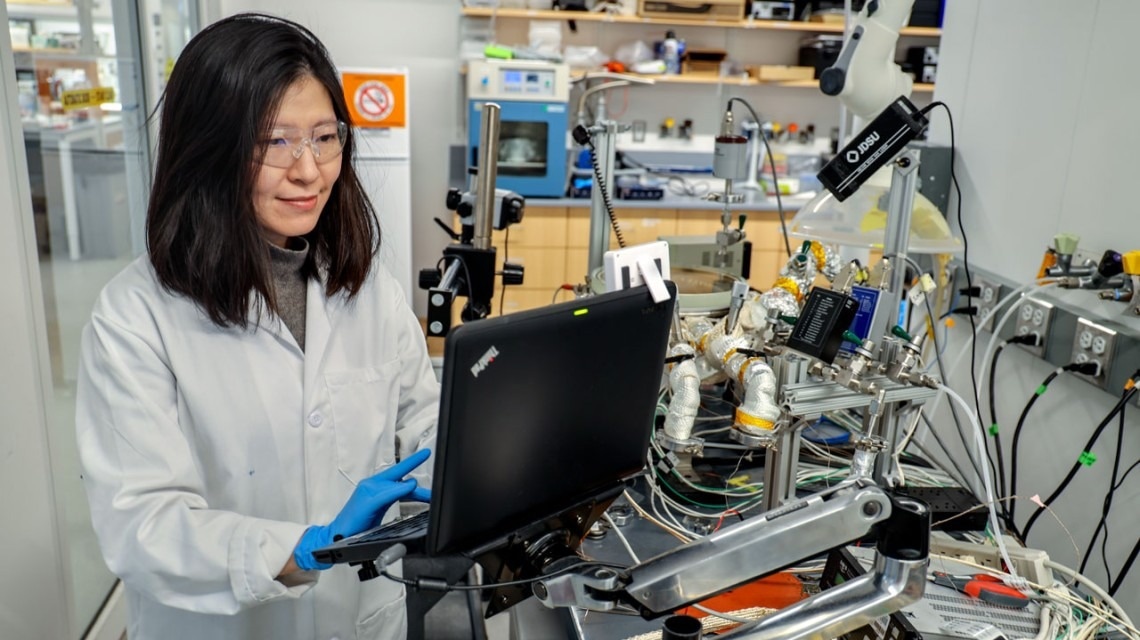

Rong Yang, assistant professor of chemical and biomolecular engineering, works with an initiated chemical vapor deposition system in her Olin Hall laboratory. Image Credit: Charissa King-O’Brien/Provided

Polymer nanoparticles have arisen as a strong tool for providing medicine to exactly the right place, at the right time, within the human body. However, their use has been restricted by the manufacturing complexity.

It can take decades for a company to design a molecular recipe and make it consistently reproducible at a large scale. There’s a bottleneck going from bench-scale synthesis to industry-scale manufacturing, and that’s what we’re trying to address.

Rong Yang, Study Lead Investigator and Assistant Professor, Smith School of Chemical and Biomolecular Engineering, Cornell University

Yang and her collaborators will be making use of AI to examine and guide the production of polymer nanoparticles in real time. As the synthesis of nanoparticles is being done with an initiated chemical vapor deposition (iCVD) system, the scientists will integrate liquid crystals that depart an “optical fingerprint” to be read by computer vision.

The consequent data will be used to train a convolutional neural network to determine information regarding the polymer nanoparticles, and further utilized for real-time, automated decision-making at the time of the assembly process.

We’ll be using liquid crystals as a solvent and also as a display, the same type you might find in your television screen. We can use them to draw a connection between the material properties, like the molecular weight, size, and morphology of the polymer nanoparticles, then link that to the optical output that we read from the AI.

Rong Yang, Study Lead Investigator and Assistant Professor, Smith School of Chemical and Biomolecular Engineering, Cornell University

Contributing expertise in liquid crystals to the study is co-principal investigator Nicholas Abbott, the Tisch University Professor in the Smith School, while expertise in artificial intelligence will come from co-principle investigator Fengqi You, the Roxanne E. and Michael J. Zak Professor in Energy Systems Engineering.

If it turned out to be successful, the study would not only produce new cyber-driven methods for manufacturing but also ultimately revolutionize how polymer nanoparticles and nanomedicines could be made.

Imagine everyone taking a slightly different version of a pill, manufactured right on the spot to have personalized medicine. Rapid characterization and feedback into the synthesis process could crack open all these possibilities that didn’t exist before.

Rong Yang, Study Lead Investigator and Assistant Professor, Smith School of Chemical and Biomolecular Engineering, Cornell University

Furthermore, Yang added that this type of manufacturing could alter the production of other products consisting of polymers, like construction materials.

The other co-principal investigators on the grant are Allison Godwin, associate professor at the Smith School, and Jan Genzer, professor of chemical and biomolecular engineering at North Carolina State University.