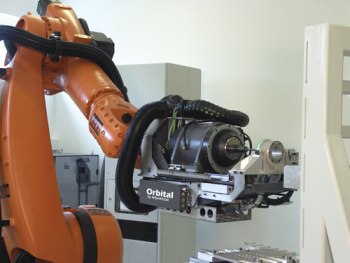

Novator has developed a new technology, called Orbital Drilling end effector, which makes robotic drilling an effective method. This technology gives the robotic arm the required rigidity while drilling holes through hard metals.

Orbital Drilling Technology

Orbital Drilling Technology

The drilling technique is identical to the helical interpolation routines that help tools in creating holes of different sizes using a lone cutter. During drilling, the tool spins around its own axis and the spindle head rotates it, so that the desired offset is created for the particular hole diameter. The spindle head incorporates an in house mechanism brought about by its inner and outer eccentric bodies that rotate mutually to enable continuous radial offset adjustment. The parameters of the drilling cycle, such as feed rate, orbital speed and spindle speed, can be programmed. This arrangement enables the robotic drilling machine to drill complex shapes in addition to the regular cylindrical, conical and countersunk holes. The drilling action is designed in such a way that it produces burr free holes in any material. The drilling machine is called E-D100; it weighs around 130 kg and is capable of creating holes having a diameter of 25 mm. The stroke length of the drill is 100 mm and the machine requires 9kW power and a spindle rotating at 30,000 rpm.

The orbital drilling technique establishes intermittent contact with the drill bit and the workpiece.This technique of drilling along with efficient air cooling system ensures that drilling of holes is accomplished with minimum lubrication. The heat generated while drilling is removed regularly, this helps in mitigating the risk of the matrix dissolving in composites and heat influenced zones in metals. The chips that come out during the drilling process are removed through an airflow extraction system. This technique of drilling is very useful for drilling stacked materials like AFRP/Aluminium and CFRP/titanium, which are used in aerospace applications. Novator supplies the corresponding software, Orbital Manager, which consists of a compensation algorithm that enables dynamic adjustment of the tool offset during drilling.