Researchers have developed two advanced haptic devices that enhance robotic teleoperation by providing more intuitive and precise control in hazardous industrial environments, addressing a long-standing gap in safety and usability.

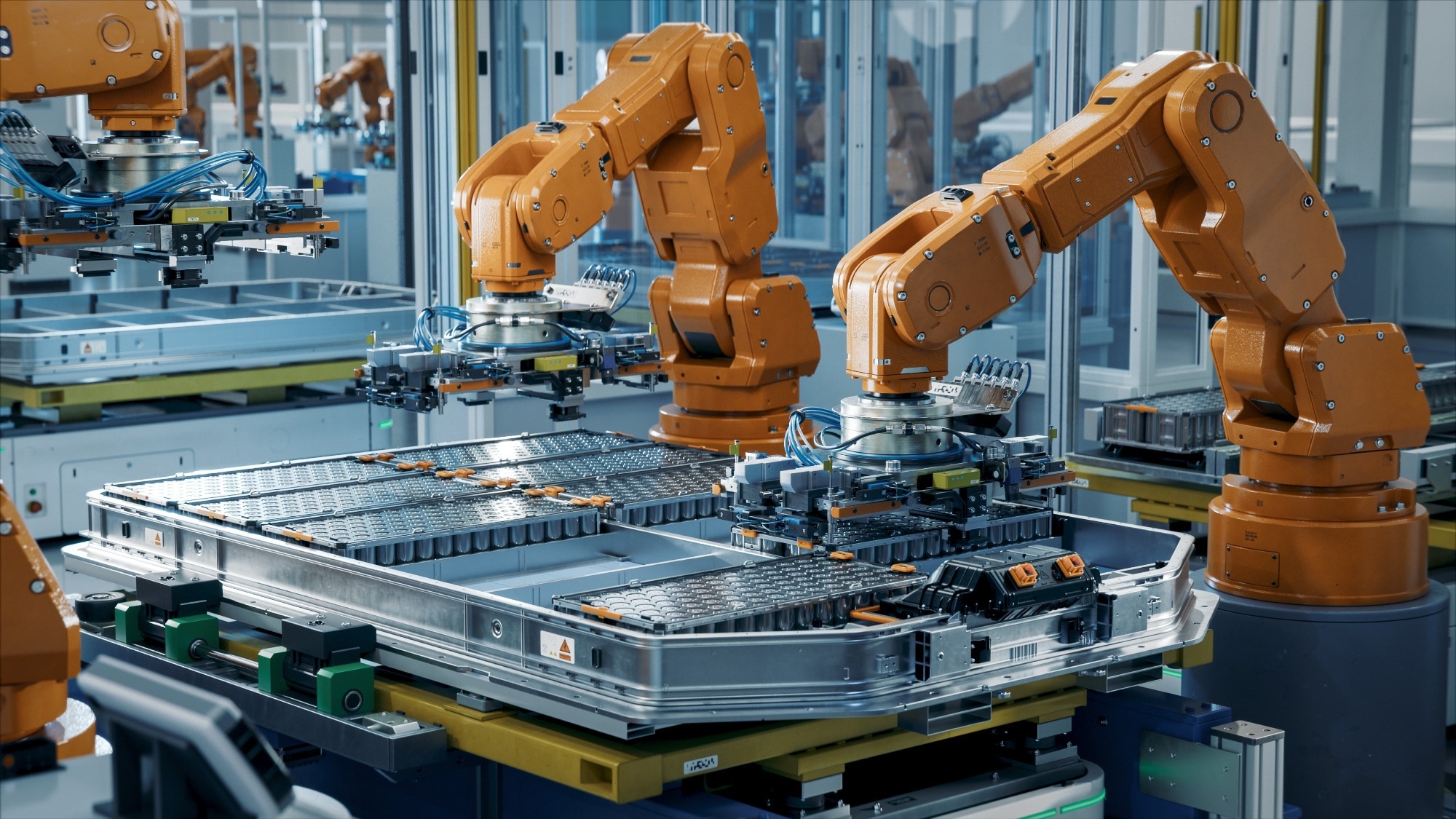

Study: Assessment of Novel Haptic Interfaces for Digital Twin Teleoperation in High-Risk Steel Production. Image Credit: IM Imagery/Shutterstock.com

Study: Assessment of Novel Haptic Interfaces for Digital Twin Teleoperation in High-Risk Steel Production. Image Credit: IM Imagery/Shutterstock.com

Published in the IEEE Transactions on Industrial Informatics, the study introduces POstick-kinesthetic feedback (POstick-KF) and POstick-visuo-tactile feedback (POstick-VF), two newly designed interfaces that deliver kinesthetic and visuo-tactile feedback, respectively. These devices improve operator control and reduce collision risks, particularly in high-stakes scenarios like steel production.

When combined with digital twin (DT) and augmented reality (AR) technologies, the system supports virtual simulation and real-time execution—enhancing both safety and efficiency. User studies revealed measurable gains in task accuracy and adaptability, especially for novice users.

Background

Despite advancements in industrial automation, many high-risk tasks in settings like steel mills still rely heavily on human oversight due to the complexity and precision they demand. Traditional teleoperation systems often lack the nuanced feedback operators need, leading to frequent errors and safety incidents. This has created a need for more intuitive, responsive control interfaces that can bridge the gap between human dexterity and robotic precision.

Focusing on DT-based teleoperation in hazardous scenarios—such as the removal of lump iron in steel production—the research team aimed to overcome the limitations of existing systems, which often demand extensive training and provide limited feedback.

POstick-KF and POstick-VF were designed to meet these challenges head-on: the former offers precise force feedback ideal for delicate tasks, while the latter combines tactile cues with visual guidance, making it effective for larger, more spatially complex environments. Both devices mimic real-world tools, allowing users to adapt quickly, even without prior experience. With DT and AR integration, operators can build proficiency in virtual settings before transitioning to live operations.

Haptic Interface Design and Functionality

The POstick-KF device delivers real-time kinesthetic feedback directly to the user’s fingertips, giving operators precise control over movements like pushing or pulling. This is especially useful in confined or sensitive workspaces. Its form factor mirrors actual industrial tools, which helps reduce the learning curve.

In contrast, POstick-VF is optimized for broader work environments. It enhances spatial awareness by merging tactile sensations with visual overlays. According to user testing, this combination significantly improved performance among novices, with participants approaching the proficiency of those using POstick-KF over time. Both devices integrate smoothly with DT and AR platforms, allowing users to rehearse complex procedures virtually before performing them in the field.

Performance and Applications

Simulation trials demonstrated that both devices outperform conventional teleoperation setups, with noticeable reductions in collision rates and improvements in task accuracy. POstick-KF proved particularly effective in tasks requiring fine force control, while POstick-VF supported faster learning and broader spatial interaction, making it an excellent tool for training. Initial lab validation has been successful, and field testing is currently underway in operational steel plants.

AR plays a complementary role by overlaying live data onto the physical workspace, helping operators maintain focus and awareness. This combination of haptic feedback, digital twin simulation, and augmented reality doesn’t just increase safety, it also helps reduce operator fatigue and cuts down on training time and costs. Beyond steel production, the system holds potential for use in other hazardous industries like mining, construction, and emergency response.

Conclusion

This research marks a notable advancement in industrial teleoperation, offering more intuitive and effective control mechanisms for challenging environments.

The POstick-KF and POstick-VF devices deliver tailored feedback solutions—whether for precision manipulation or skill-building—and integrate seamlessly with DT and AR technologies. Together, they help reduce risk, improve training outcomes, and make complex robotic systems more accessible to a wider range of users. As real-world deployment continues, this approach could reshape how humans safely and effectively interact with machines in high-risk settings.

Journal Reference

Park, J., Kim, Y., Choi, I. S., Choi, S.-W., Choi, S., & Kim, K. (2025). Assessment of Novel Haptic Interfaces for Digital Twin Teleoperation in High-Risk Steel Production. IEEE Transactions on Industrial Informatics, 1–11. DOI:10.1109/tii.2025.3556077. http://dx.doi.org/10.1109/TII.2025.3556077

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.