Increasingly integrated with digital electronics and sensors, actuators play a critical role in modern mechanical systems across industries. From robotics to automotive applications, they are indispensable in industrial mechatronic systems, providing the motion control and precision necessary for advanced operations.

At their core, actuators are energy converters that transform external input energy into controlled mechanical motion. The type of energy input depends on the actuator’s design and purpose. Examples include:

- Piezoelectric, electromagnetic, and magnetostrictive actuators: These use voltage, current, or charge as inputs.

- Thermal actuators and shape memory alloys (SMAs): These rely on temperature changes.

- Fluid power actuators: Hydraulic and pneumatic actuators utilize fluid pressure or flow.

The primary outputs of actuators are force and motion (stroke), while derived outputs, such as power and work, measure their overall performance. Control mechanisms ensure precise operation by processing input signals.

Control systems for actuators fall into two categories:

- Open-Loop Systems: Operate on pre-programmed commands without feedback, making them simpler and cost-effective but less accurate.

- Closed-Loop Systems: Use feedback to adjust control signals dynamically, enabling precise operation at the cost of increased complexity and expense.1,3

Image Credit: Sergey Ryzhov/Shutterstock

Image Credit: Sergey Ryzhov/Shutterstock

Key Components of Actuators

Actuators are built around several key components, each playing a critical role in their operation and performance. At the foundation is the input power source, which provides the energy required for the actuator to function. Depending on the design and purpose, this energy can come from hydraulic, pneumatic, electrical, thermal, magnetic, or mechanical sources, offering flexibility across various applications.3

This energy is transformed into motion or force through the actuator mechanism, which varies depending on the actuator type. Electromagnetic actuators, for example, generate torque and force using magnetic energy, combining electrical and magnetic circuits to produce the necessary fields and flux.

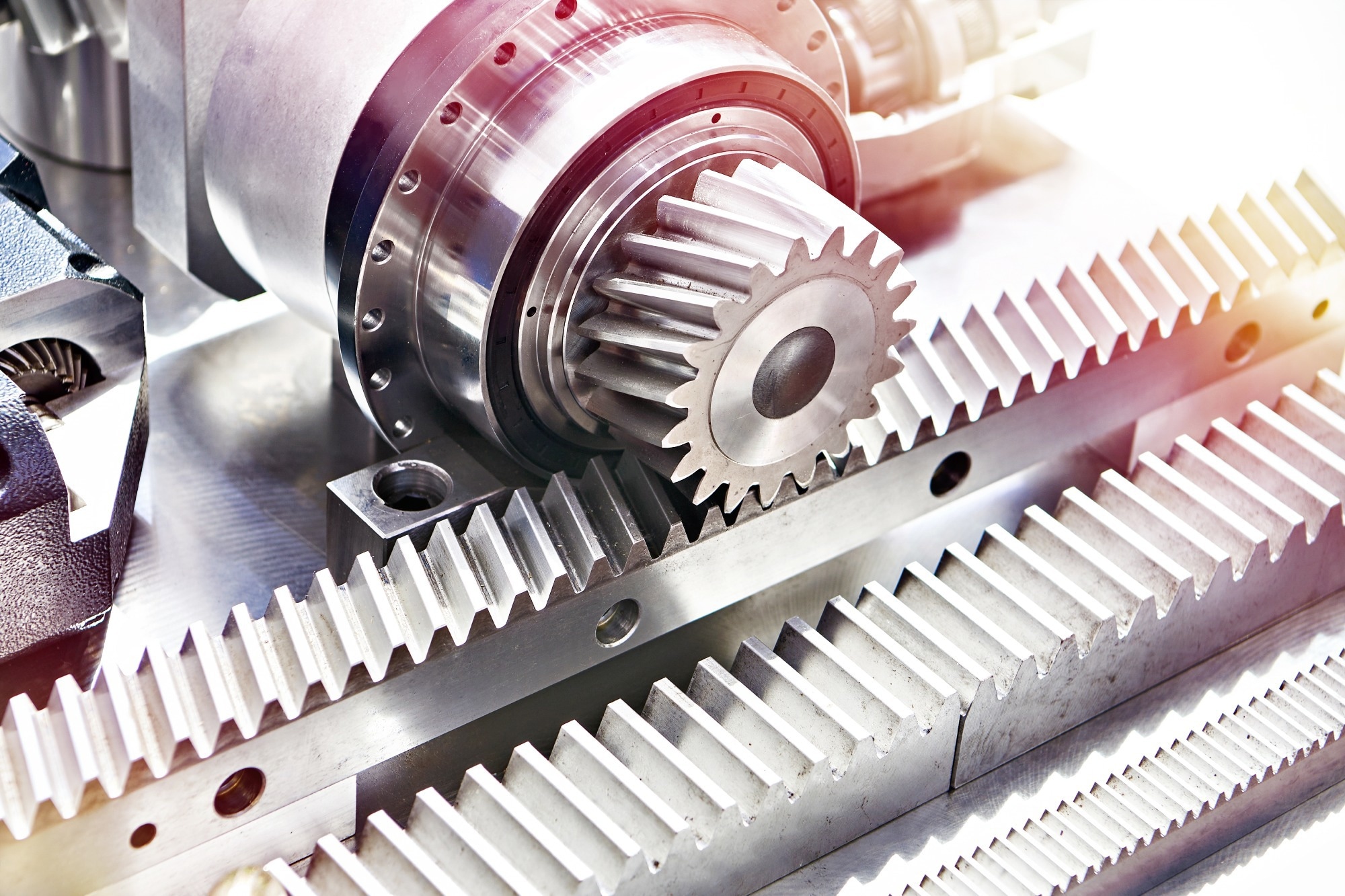

Pneumatic actuators use compressed air or gases to create linear motion, making them cost-effective and reliable. Hydraulic actuators leverage pressurized fluid for exceptional strength, particularly in heavy-load applications. Piezoelectric actuators rely on the contraction and expansion of specialized materials under voltage, enabling rapid and precise movements. Mechanical actuators, utilizing gears, pulleys, rails, or chains, provide robust solutions tailored to specific performance needs.

The result of this process is the actuator’s output—the physical motion or force produced. Outputs vary by design, with rotary actuators, such as motors, delivering circular motion, while linear actuators, like hydraulic or pneumatic types, provide straight-line movement. These outputs are integral to the functionality of countless mechanical systems, from industrial machinery to advanced robotics.

To ensure precision and reliability, many actuators incorporate feedback systems. These systems continuously monitor performance metrics such as position and speed, comparing actual outputs to desired outcomes. By making real-time adjustments, feedback systems minimize deviations, ensuring stable and accurate operation. This capability is particularly vital in high-precision fields like robotics and aerospace, where exact performance is non-negotiable.3

Types of Actuators

Actuators are categorized based on their energy source and mechanism. Key types include:

- Hydraulic Actuators: Known for their strength and ability to handle heavy loads, these actuators are commonly used in industrial and aerospace applications.

- Pneumatic Actuators: Cost-effective and versatile, these are widely used in industrial automation for their reliability and flexibility.

- Electric Actuators: Valued for their precision and efficiency, they are often used in robotics and consumer electronics.

- Thermal Actuators: These utilize material expansion caused by heat for movement.

- Piezoelectric Actuators: These offer rapid, precise movements, making them ideal for applications requiring high accuracy, such as micromechanical systems.

Applications of Actuators

Actuators are integral to a wide range of systems, driving efficiency and innovation across various industries. In industrial automation, they are commonly used in robotic welding, servopresses, packaging machines, and injection molding, with pneumatic actuators standing out for their flexibility, reliability, and cost-effectiveness.

In robotics, electromagnetic actuators offer scalability and precision, while hydraulic actuators are preferred for high-power and rugged applications in mobile robots. Aerospace and automotive industries also rely heavily on actuators, particularly hydraulic ones, which are valued for their durability, speed, and ability to deliver precise motion control in systems like brakes and steering.

In consumer electronics, piezoelectric actuators enhance smart home devices by enabling motorized adjustments and precise movements. Meanwhile, in healthcare, actuators play a critical role in surgical robots, diagnostic equipment, and mobility aids, where precision, safety, and adaptability are paramount. These versatile components continue to enable advancements in technology across numerous fields.3,4,5

Emerging Trends and Innovations

The world of actuators is evolving rapidly, with trends like smart technology, miniaturization, and energy efficiency taking center stage. These advancements are driving the creation of more precise, compact, and sustainable solutions across various industries.

Smart actuators are a prime example of this progress. These integrated devices combine artificial and smart materials to provide unique functionalities, such as dampening and actuation, in response to external triggers like heat, light, electricity, magnetism, or humidity. This versatility opens doors to applications that demand adaptability and responsiveness.

In parallel, the push for miniaturization is largely shaped by specific application needs. Take robotics, for example. The demand for smaller, more agile robots capable of navigating confined spaces—such as those required in microsurgery, microassembly, or inspection—has accelerated the development of miniature actuators. Products like the RSF-Supermini actuator series, which are small enough to fit inside a robotic finger, illustrate how far this innovation has come.

Another critical focus is energy efficiency. By reducing heat generation and energy consumption, efficient actuators improve performance and extend operational times. Innovations like electromechanical design optimization and the use of advanced materials have played a significant role in creating actuators that not only perform better but also align with sustainability goals.

These emerging trends are reshaping industries, offering smarter, smaller, and greener solutions that pave the way for more innovative applications.5,6

Conclusion

Actuators are the backbone of modern robotics, converting energy into precise motion that enables robots to perform complex and essential tasks. Their seamless integration with sensors and control systems has made them indispensable in advancing automation and solving real-world challenges.

With ongoing innovations in materials, efficiency, and design, actuators are anticipated to open up new capabilities in robotics—from enhancing precision in surgical systems to powering autonomous technologies. As robotics continues to evolve, actuators will remain a driving force behind the industry’s most groundbreaking achievements.

References and Further Reading

- Introduction to Actuators [Online] Available at https://www.nielit.gov.in/gorakhpur/sites/default/files/Gorakhpur/Alevel_iot_04_May_2020_SM.pdf (Accessed on 09 December 2024)

- Actuators, Encoders, Relays and Switches [Online] Available at https://ieda.ust.hk/dfaculty/ajay/courses/ieem110/lecs/3_actuators.pdf (Accessed on 09 December 2024)

- Inamuddin, B., Rajender, A., Abdullah, M. (2020). Actuators: fundamentals, principles, materials and applications. https://www.researchgate.net/publication/348035746_Actuators_Fundamentals_Principles_Materials_and_Applications

- Hilmi, A. H. (2023) Actuators in Automation https://www.researchgate.net/publication/370325865_Actuators_in_Automation

- Yuan, Z. (2023). Current status and prospects of actuator in robotics. Applied and Computational Engineering, 11, 181-191. DOI: 10.54254/2755-2721/11/20230232, https://www.ewadirect.com/proceedings/ace/article/view/4291

- Zheng, Q., Xu, C., Jiang, Z., Zhu, M., Chen, C., & Fu, F. (2021). Smart Actuators Based on External Stimulus Response. Frontiers in Chemistry, 9, 650358. DOI: 10.3389/fchem.2021.650358, https://www.frontiersin.org/journals/chemistry/articles/10.3389/fchem.2021.650358/full

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.