I am a doctoral candidate at The University of British Columbia, Kelowna, Canada, at the Advanced Control and Intelligent Systems (ACIS) Laboratory, now based at the University of Victoria.

My research involves applying human-robot collaboration to industrial settings and how we could make communication natural and intuitive for the human partners involved to create a safe working environment.

Canada and, by extension, the universities I am affiliated with provide world-class research facilities and a multi-cultural setting that fosters partnerships across countries and disciplines. In the current research climate, especially in projects that strive to be globally relevant, collaboration driven by perspectives from experts across the world is necessary for success.

I was given the opportunity to work as an intern at TRIUMF, UBC, under the Mitacs Globalink program, and my experience working at the excellent facility, the quality of research carried out, and the pathways to graduate studies prompted my decision to return to Canada.

How did you become involved with this research project in particular?

I had the freedom to select a research topic that excited me in a laboratory that works closely with multiple industrial partners, especially in the manufacturing sector.

I was especially intrigued by the question of how as researchers and engineers, we can design human-robot collaborative systems that can be easy to use and safe to deploy in industries. Thus, focusing on multimodal, natural communication in industrial settings is the mainstay of my Ph.D. project.

Could you summarize the results of the paper?

After an extensive literature review on Industry 4.0, smart manufacturing, and human-robot collaboration, my co-authors and I realized that there was a gap in the very definition of what a partnership could look like between the human carrying out cognitive and dexterous tasks and the robot bringing efficiency and repeatability.

This topic was primarily tackled in this particular paper apart from presenting a comprehensive survey and review of the field. A novel taxonomy of the various forms of interaction between humans and robots has been proposed based on the accepted definitions for the capabilities of autonomous vehicles.

We believe versatile definitions would guide future research in this exciting and multidisciplinary field.

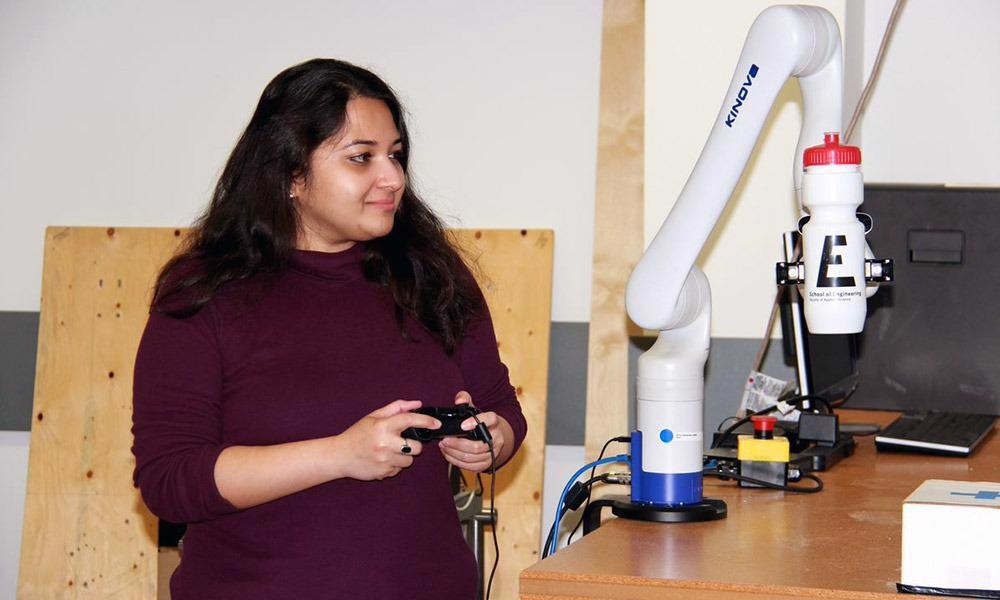

UBCO doctoral student Debasmita Mukherjee, with the School of Engineering’s Advanced Control and Intelligent Systems Laboratory, is looking at ways to program robots so they can work safely alongside people. © School of Engineering’/The University of British Columbia

Multidisciplinary research is more than just working with researchers in different fields but must also take a global approach to collaboration. What more could be done to improve connections between international communities, especially those between women in STEM?

While universities are making great strides in engaging younger women in taking part in STEM, there is also a need to collaborate with multidisciplinary, diverse teams of researchers. That has motivated me to reach out to the four corners of the world and bring together researchers with complementary expertise in multi-faceted human-robot collaboration research with ACIS.

More importantly, we hope that this endeavor will provide a more comprehensive context in terms of training data and model design to develop systems that can be physically, psychologically, and socially safe to deploy in a multitude of applications globally. Half of the team members we have built are women in STEM, and their expertise spans from engineering to linguistics to economics and psychology.

Many initiatives aim to inspire future career paths in the robotics field. What actions could be taken to encourage STEM career paths, and what efforts have you seen from your field in particular to help this?

Communication and outreach activities motivate everyone equally. Articles that highlight work by a diverse group of researchers is perhaps one way to motivate early-career researchers and students to pursue careers in STEM and remove some of the biases that may be present.

Research fields such as human-robot collaboration (HRC) strive to remove employment barriers posed by expertise or physical ability, among others, and potentially create a more harmonious workplace for all genders, especially in the environment that has traditionally been designated for males.

Another consideration in the context of HRC, in an environment where machines have to work with humans of all genders, one has to be careful that the training of such intelligent systems is comprehensive and unbiased. Thus, the topics we as researchers and engineers choose to devote our efforts to, the designs we select, and the data we use all leave indelible effects on society. Due rigor must be put in to ensure robustness when implemented outside the real world in the controlled conditions of our labs.

Collaborative working with robots is an area of research that has received interest from academics and industry alike. What impact do you think this relationship will have on the future of the manufacturing sector?

Some industries within the manufacturing sector, such as automotive, where tasks are pre-programmed and repetitive, have reaped the benefits of automation. On the other hand, other industries that require customized products and involve numerous tasks that require dexterity, precision, and cognitive decision-making have not benefitted from automation.

In industries that produce tailor-made solutions, intelligent robots that can be adaptive to the task must work in tandem with humans and leverage their strengths to bring greater intelligence to industrial systems.

Industries like mining and construction can benefit from robots by assigning physically taxing and unsafe tasks to the robot partner. Recent events exacerbated by the pandemic further prove the need for an environment in which humans can work remotely and safely while the machines carry on the manufacturing tasks without interruption.

© Blue Planet Studio/Shutterstock.com

What characteristics should a robot system possess to be a safe and effective member of a human-robot team?

A major aspect of human-robot collaboration is to ensure the safety of the human partner. These intelligent robots and more generally adaptable systems would introduce hereto unknown and complex faults that are dependent on human behaviors and various components of the system. To ensure the safety and effectiveness of task execution, all fault sources must be considered to develop a safety framework.

Such a framework must include not just physical safety factors, i.e., factors that can jeopardize the bodily safety of humans, but also psychological ones. Psychological safety factors stem from instances that can disrupt the psychological well-being, such as issues of trust in the robot and adaptability of the human to their robotic partner.

As we introduced in our paper, robots in the human-robot team can possess different levels of intelligence. Safer operations largely depend on the tasks at hand, each of which will require specific levels of intelligence for performance, efficacy, and safety.

Our attempt focused on clarifying the relationship between humans and robots in designing a successful team. For example, if a dexterous handover is necessary for a scenario, the robot has to be as dexterous and intelligent as the human for a successful outcome.

Many are wary of integrating robots into the workplace. What are the benefits of working alongside intelligent systems?

While there are challenges that could occur from integrating intelligent systems, the advantages of doing so are significant. Generally, automation confers higher efficiency and accuracy in carrying out tasks.

Under human-robot collaboration, if robots are assigned non-ergonomic, repetitive tasks, then physical prowess will no longer be a pre-requisite for specific jobs, opening up the possibility of employing a broader reach of the population.

Safety is a significant driver of research and traditionally, safety-critical industries such as mining would greatly benefit from these systems. Additionally, a major constituent of research in human-machine interaction research is how to design seamless, intuitive communication between humans and machines. This will relieve workers from dangerous, dirty, and dull tasks and allow them to focus on jobs that require more cognitive skills and creativity.

Apart from all of these considerations, intelligent systems are slated to be more fault-tolerant and would provide a higher degree of robustness to disturbances and noises in industries.

Other than the manufacturing sector, do you predict that other fields will begin to incorporate collaborative working with robotics?

Apart from the manufacturing sector, which mainly deals with "industrial" human-robot collaboration (HRC), the field of social and service HRC deals with applications of robots operating within social situations.

The examples of such research are numerous, ranging from chatbots to elderly and childcare to receptionists and restaurant service staff, to name a few. The challenges associated with such applications deal with inculcating trust or creating engaging communication systems.

While the general methods and techniques of artificial intelligence, data-driven machine learning and established control strategies are utilized in both fields, application-specific heuristics must be instilled into systems to make them ready to be deployed in the real world.

Did you face any major challenges in this research?

A common challenge in machine learning applications is the existence of and access to the relevant datasets. I, too, have faced similar challenges in carrying out my research. If datasets are available, it is challenging to gauge their quality regarding inherent biases and whether their quantity is sufficient to represent the problem at hand. This is especially true for human-robot collaboration research, where biases in datasets have real-world consequences, and researchers must carry out due diligence in selecting or creating their research data.

Significant efforts are dedicated to more varied data generation and designing model architectures that can better use existing datasets.

In my work, I am tackling this problem by first formulating the framework on existing data, then creating dedicated datasets and fine-tuning my machine learning-based models by myself and for future researchers.

What was the most exciting moment during your involvement with this project?

As with any other research, after months of effort, when an experiment is successful, it is a moment of joy like no other.

For me, as a researcher trained in Engineering Physics and having migrated to the field of machine learning, the first time my framework worked was quite exciting. While that was short-lived, the cases where it did not work were markedly more exciting because they opened up avenues for investigation and potentially more exciting research questions.

This survey pointed me toward multimodal communication between humans and robots. My subsequent experiments have led me to understand better what 'natural' communication looks like for this exciting collaboration between man and machine.

Where can our readers go to stay up to date with this field?

We will continue disseminating our results in major robotics journals and conferences as this research will remain active.

Stay up to date with Advanced Control & Intelligent Systems Laboratory

About Debasmita Mukherjee

Debasmita is a Ph.D. candidate at the School of Engineering, The University of British Columbia, Canada and works at the Advanced Control and Intelligent Systems lab at the University of Victoria. She is carrying out her research under the supervision of Dr. Homayoun Najjaran who is the principal investigator of this laboratory. Inspired by the dynamics of human teams and the possibility of highly adaptive and flexible robots with applications in Industry 4.0 and smart manufacturing, her research aims to develop and validate a framework for human-robot collaboration to execute manufacturing tasks.

Debasmita's research is funded by the UBC Vice-President Research + Innovation (Research Expansion) project for the incorporation of human-robot collaborative strategies for the labour-intensive manufacturing sectors in partnership with UBC Composites Research Network (CRN) and UBC Data Science Institute (DSI). She has held a research assistantship at UBC Okanagan and as a visiting student at UVic since September 2019.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.