The Siemens Industry Automation division has extended its "Totally Integrated Automation Portal" (TIA Portal) engineering framework with numerous new functions. Version 12 enables all Siemens drives of the Sinamics G converter series to be parameterized via the TIA Portal, and additional diagnostic functions have been integrated. Among other things, the safety functionalities have been extended for Simatic S7-1500 and the Profinet communication performance has been expanded.

The programming languages have been trimmed for even greater efficiency and new security functions provide improved protection of know-how, and better security against copying and access. Within the framework of the new version of the TIA Portal there are also updates for engineering tools for the configuration, programming, commissioning and servicing of the Siemens automation devices and drive systems. These include, for example, the following engineering systems: Simatic Step 7 V12 for Simatic controllers, Simatic WinCC V12 for HMI systems (Simatic HMI) and Sinamics Startdrive V12 for the Sinamics G converter family.

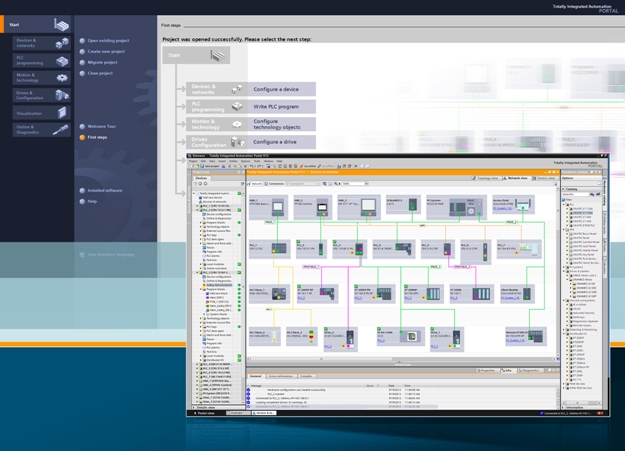

The Siemens TIA Portal enables users to perform automation and drive tasks quickly and intuitively. The software architecture is designed for high efficiency and user-friendliness, and it is suitable for both first-time users and experienced users. It offers a standardized operating concept for controllers, human machine interface (HMI) and drives, for shared data storage and automatic data consistency, for example during configuration, communication and diagnosis, and also offers powerful libraries covering all automation objects.

In its latest Version 12, Siemens has extended the TIA Portal to include numerous functions for drive integration, system diagnosis, safety, Profinet communication, security and programming languages:

Seamless drive integration: With the "Sinamics Startdrive V12" engineering system, integrated into the TIA Portal, the Siemens Sinamics G drives can be quickly and efficiently parameterized for the automation task and then put into service. The drives are also integrated automatically into the system diagnosis. Another new feature of TIA Portal V12 is the scalable and flexible motion functionality with the new Simatic S7-1500 controllers for drives connected on a centralized or distributed basis. Blocks compliant with PLCopen are available for the programming, as well as motion-control technology objects for the control tasks and parameterization of the converters. This enables typical, non-synchronized motion processes to be programmed and tested. Absolute and relative positioning, referencing, speed specification and absolute encoders are supported.

Integrated system diagnostics: The configuration of the diagnostics is integrated in the system for user-friendly operation and can be activated with just a single click. In the case of new hardware components, the diagnostic information is updated automatically. With an improved and standardized display concept, status or error messages are visualized in exactly the same way – not only in the TIA Portal and on the HMI devices, but also in the web server and on the display of the new Simatic S7-1500 controllers. The real-time trace function for the controllers and drives enables user programs and motion applications to be diagnosed with great precision and the drives to be optimized.

Integrated safety functionality: The "Step 7 Safety Advanced V12" engineering system for the TIA Portal integrates the safety engineering of the Simatic S7 controllers including the Simatic S7-1500 devices. An optimized compiler with an efficient code offers fast processing of the failsafe program. Also new are the autonomous prioritization and timing setting, as well as the visual monitoring of the error cycle time. A simplified acceptance printout as well as the new functional signature for the user program shorten the acceptance procedure, even if modifications have been made. An additional safety stage for the safety configuration increases the protection against unauthorized changes. Sinamics Startdrive in Version 12 or higher also supports failsafe functions for Sinamics converters.

Powerful Profinet communication: Version 12 of TIA Portal now also supports Profinet functions Media Redundancy Protocol (MRP) and I-Device.

Multi-stage security: The concept of "Security Integrated" in TIA Portal V12 in connection with the new Simatic S7-1500 controllers extends from block protection to communication integrity and helps users to safeguard their applications. Integrated functions for safeguarding know-how, e.g. against the cloning of machines, help to protect against unauthorized access and modification. The copy protection uses the Simatic memory card, on which individual blocks are linked to the serial numbers of the original memory card. This should ensure that programs only run with the configured memory card and cannot therefore be copied. Access protection addresses unauthorized configuration changes. To this end, different user groups can be assigned separate rights by means of authorization stages. Special mechanisms are geared toward recognizing modified engineering data – in order, for example, to protect the data transmitted to the controller from unauthorized manipulation.

Optimized programming languages: Simatic Step 7 V12 provides the new Simatic S7-1500 controllers with optimized compilers for the programming languages STL (statement list), FBD (function block diagram), LAD (ladder logic) and SCL (structured control language). SCL now contains the programming with slice-access for fast access to individual parts of variables and for the export of SCL code. The "calculate box" function for complex arithmetic operations, as well as indirect addressing and implicit type conversion, is also supported for the new controllers in LAD and FBD. Further innovations are 64-bit data types (LREAL, LINT, LWORD), automatic acceptance of the current values as initial values, block expansion during operation to avoid data loss and block sizes of up to 16 MB. Integrated symbolic programming enables consistent data access, increased transparency during project creation, and minimization of errors by automatically updating the project data.

In designing the TIA Portal V12, particular importance was attached to the reuse and compatibility of existing projects and software: for example, when switching from Simatic S7-300/400 to S7-1500, projects can be reused and S7-1200 programs can be copied and pasted into S7-1500. Projects created in Version 11 can also be opened and saved in Version 12.