Nov 6 2017

Scientists are currently working toward developing new fleets of autonomous 'self-optimizing' forklift trucks capable of working efficiently and safely in warehouses alongside human co-workers, and also having the potential to automatically adapt to different work requirements.

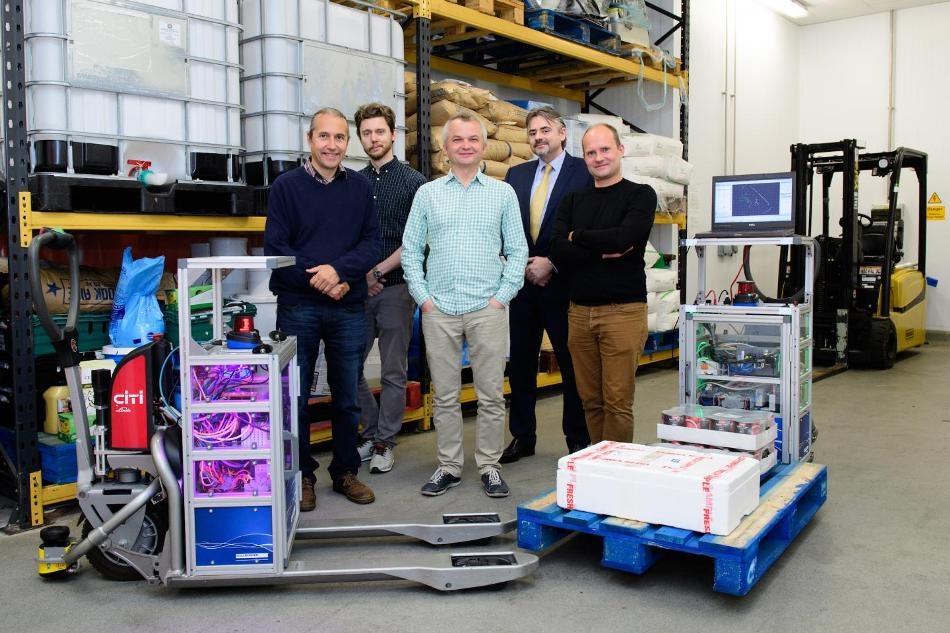

Pictured L-R with the forklift prototypes is Professor Tom Duckett, Principal Investigator for the University of Lincoln's ILIAD team, Dr Martin Magnusson from Örebro University, and the rest of the team at Lincoln, Dr Grzegorz Cielniak, Mark Swainson, and Dr Marc Hanheide. (CREDIT Chris Vaughan/ University of Lincoln)

Pictured L-R with the forklift prototypes is Professor Tom Duckett, Principal Investigator for the University of Lincoln's ILIAD team, Dr Martin Magnusson from Örebro University, and the rest of the team at Lincoln, Dr Grzegorz Cielniak, Mark Swainson, and Dr Marc Hanheide. (CREDIT Chris Vaughan/ University of Lincoln)

The aim of the project, a multinational partnership between robotics specialists in the UK, Sweden, Italy and Germany, is to allow deployment of next generation automated guided vehicles (AGVs) into existing warehouse facilities in order to support tasks such as palletizing, packing and transporting goods.

The four-year project, known as Intra-Logistics with Integrated Automatic Deployment (ILIAD), is funded with a huge grant of 7 million Euros from the EU's Horizon 2020 fund. The consortium is headed by Örebro University in Sweden, and includes University of Lincoln, UK, University of Pisa, Italy, and Leibniz University, Hannover, Germany, working with major industrial partners Bosch, Kollmorgen Automation, ACT Operations Research, Logistic Engineering Services and Orkla Foods.

ILIAD will deliver vital technological advances into an integrated system ready for low-cost, easy deployment and without the requirement for key infrastructure investments. A main requirement is that each robot is 'human aware' - provided with improved computer vision and artificial intelligence in order to detect, track and then predict the behavior of humans and also to plan movements based on the machines' own observations of warehouse lay-outs and activity patterns.

Significantly, each robotic vehicle will be self-optimizing, learning from self-collected data over time, allowing the fleets to be fully scalable with the option of removing or adding robots at any time.

While the aim is to produce a reliable robotic solution flexible enough for supporting intra-logistics in a number of different industries, the researchers will make use of the fresh food sector as their development setting. This is because of the industry's mainly challenging demands: need for total traceability, high cost of wastage, short shelf life of products, and pressure for rapid responses to changing market requirements.

The food industry is considered to be the largest manufacturing sector in Europe with an annual turnover of a trillion Euros, supporting over four million jobs. The UK food industry is worth £100bn to the UK economy annually.

The Lincoln team, as part of their contribution to the project, will focus on prolonged operation of the ILIAD system, including learning and predicting activity patterns of human co-workers, and maintenance of environment maps over time.

They will also produce qualitative models for human-robot spatial interaction, systems integration and systems architecture. The work will cover experimental testing at University of Lincoln's National Centre for Food Manufacturing in Holbeach, Lincolnshire.

Our goal is to deliver an economical, flexible robotic solution that can be easily deployed and integrated into current warehouse facilities and which guarantees efficient and safe operation in environments shared with humans. The project will push the state-of-the-art in human-robot interaction, overcoming persistent barriers to greater adoption of automation in logistics operations in many industries, starting with the food sector. The fleets will be self-deploying and self-optimizing, removing much of the capital cost and disruption of introducing robotic technologies. Most importantly, though, we will show that autonomous vehicles can operate safely and efficiently alongside human co-workers and human driven vehicles in complex, dynamic warehouse settings.

Professor Tom Duckett, Director of the Lincoln Centre for Autonomous Systems (L-CAS) at University of Lincoln and Principal Investigator on the ILIAD project

Mark Swainson, Head for Research at the University of Lincoln's National Centre for Food Manufacturing, said: "The massive scale of food volumes moved by the sector means that being able to do this quickly and efficiently can make the difference between business success or failure.

"Movement costs "per pallet" and "per case" are tracked as Key Performance Indicators in most warehousing and distribution operations. Robots seamlessly integrating alongside humans, often working collaboratively, will unlock significant productivity advances in the sector while also serving to help address anticipated challenges resulting from increased competition and escalating operating costs over the coming years."

Coordinator of the project is Dr Achim Lilienthal, Professor of Computer Science at Örebro University and Head of the Mobile Robotics and Olfaction Lab at Örebro University.

He said: "In addition to the development of self-deploying and self-optimizing fleets of autonomous vehicles that are able to unwrap pallets and manipulate stacked goods, this project is crucially interested in safety and the collaboration of robot and humans. Safety is addressed by developing means of highly reliable human detection and tracking, and a systematic integration of safety considerations into the ILIAD system."