Subsea oil activities have become an essential part of the worldwide energy landscape. With onshore oil reserves depleting and energy demand growing, the industry has shifted its focus to the immense riches beneath the ocean surface.

These operations entail a complicated set of activities, such as exploration, drilling, and production, all carried out in the seabed's harsh and frequently hazardous environment. Subsea oil operations provide particular challenges that necessitate inventive solutions to assure the safety of the workers and provide efficiency simultaneously.

The Role of Robotics

In recent years, robotics technology has played a pivotal role in revolutionizing subsea oil exploration and maintenance. Robots have transformed how firms approach subsea operations, allowing them to accomplish jobs previously thought too risky or logistically tricky for human personnel.

Remotely Operated Vehicles (ROVs) have become critical equipment. ROVs are remotely teleoperated vehicles with advanced technology, such as high-definition cameras, sonars, manipulator arms, and cutting instruments. These ROVs are operated from the surface by competent operators and can conduct sophisticated operations in harsh underwater environments.

Autonomous Underwater Vehicles (AUVs) are also gaining traction in subsea oil operations. AUVs are self-driving vehicles with navigation systems and sensors, allowing them to traverse various terrains and collect vital data. Because AUVs may be programmed to perform predetermined missions, they are perfect for pipeline inspections and environmental monitoring.

Furthermore, integrating artificial intelligence and machine learning in robotic systems has significantly enhanced their capabilities. These intelligent algorithms allow robots to analyze complex data in real time, identify patterns, and make informed decisions. This integration has streamlined the decision-making process and increased the overall efficiency of subsea operations.

Cutting-Edge Robotic Technologies

Creating cutting-edge robotic technology has been critical in addressing the problems of subsea oil operations. Improving sensors and imaging systems is one of the most remarkable breakthroughs.

ROVs and AUVs can record crisp and detailed images even in the abyssal depths of the ocean depths, thanks to high-definition cameras and innovative illumination systems. Multibeam and side-scan sonars, for example, provide critical data for mapping the seafloor, finding subsea structures, and identifying possible dangers.

Furthermore, by combining robots with new communication technology, real-time data transfer from the bottom of the ocean to onshore-based facilities has been made possible. This capacity enables operators to continually monitor processes and respond quickly to any concerns during subsea activities.

The development of reliable communication networks, including underwater-based acoustic and satellite communication systems, has dramatically increased the efficacy and safety of subsea operations.

Robotic intervention tools have significantly progressed, enabling more accurate and effective maintenance and repair procedures. Robots, equipped with manipulator arms and tools like cutting and welding equipment, can execute intricate tasks with precision. These intervention technologies have decreased the requirement of humans in dangerous settings, significantly improving subsea operations' safety.

Safety Benefits of Robot Inspections

Integrating robotics in subsea oil operations has brought about numerous safety benefits, mitigated risks, and ensured the well-being of workers and the environment. By delegating high-risk tasks to robots, companies can minimize the exposure of human workers to hazardous conditions, such as extreme pressure, corrosive substances, and unpredictable underwater currents.

The robots significantly reduce the likelihood of accidents and injuries during subsea operations. Furthermore, robotic inspections are crucial in detecting early structural anomalies and equipment failures.

Advanced sensors and imaging systems enable robots to identify potential issues before they escalate into critical problems. By proactively detecting and addressing these issues, operators can prevent catastrophic events, such as equipment malfunctions or pipeline ruptures, which could lead to environmental disasters like oil spills.

The preventative methodology of utilizing technologies such as integrating robotics and advanced sensors to maintenance and inspection has proven instrumental in ensuring the integrity and safety of subsea oil infrastructure.

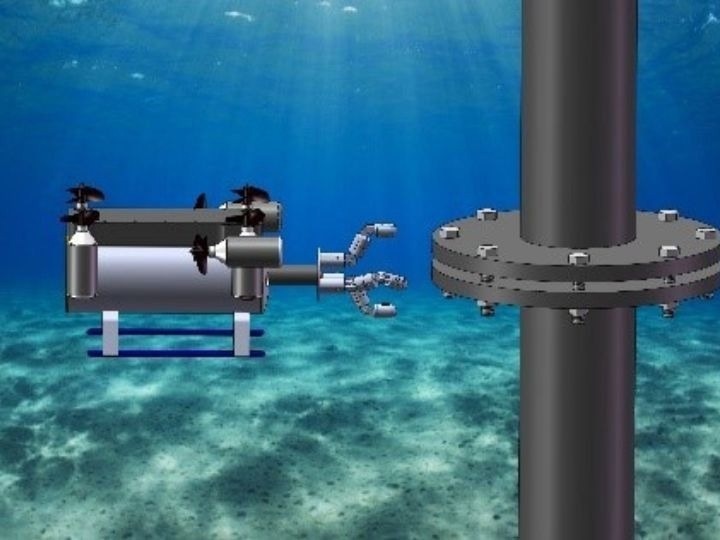

Rendering of the SmartTouch technology now in development. Image Credit: University of Houston

SmartTouch, Making Subsea Oil Operations Safer

Several case studies show the value of robotic inspections in subsea oil operations. One significant example is underwater pipeline inspection ROVs outfitted with modern imaging equipment. Early corrosion diagnosis allows operators to take preventive steps, such as spraying protective coatings or performing targeted repairs, to extend pipelines' lifespan and structural integrity.

Researchers at the University of Houston are building an autonomous robot to detect possible pipeline leaks and structural breakdowns during underwater inspections. The revolutionary technology will make inspections considerably safer and more cost-effective, preserving aquatic ecosystems from disaster.

ROVs equipped with several wave-based touch sensors, video cameras, and sonars, which can swim along subsea pipelines for inspection and predictive maintenance, are being developed at UH as part of their SmartTouch technology.

Researchers believe the SmartTouch system will serve as a design blueprint for future advancements in robotic technologies.

The future of subsea oil operations appears promising, with continuous advancements in robotic technologies and their integration with other cutting-edge solutions. Swarm robotics, in which numerous robots collaborate to accomplish complicated tasks, is projected to improve the efficiency of subsea inspections and maintenance operations.

The utilization of novel materials in the construction of these robots, such as anti-corrosion metals and polymer composites, will allow the robotic systems to survive the severest of aquatic environments.

Integrating robotic systems with upcoming technologies like 5G technology and the Internet of Things (IoT) will also transform modes of data gathering, analyzing, and sharing in real-time. This convergence will allow operators to make more informed decisions based on accurate, real-time data, enhancing productivity and minimizing risks.

Conclusion

In the evolving landscape of subsea oil operations, robotics has emerged as a game-changing force, driving unprecedented safety and efficiency improvements.

With onshore reserves dwindling, the focus has shifted to the ocean's depths, where operational complexities demand innovative technological solutions. Robotics, particularly ROVs and AUVs, equipped with advanced sensors and imaging systems, have proven pivotal in navigating these challenges.

These robotic systems not only reduce human exposure to subsea risks but also enhance the reliability of operations through real-time data analytics, early malfunction detections, and precise maintenance tasks.

Recent developments, from the University of Houston's SmartTouch technology to potential integrations with 5G and IoT, point to a future where the partnership between subsea operations and robotics continues to deepen. This merging promises a safer, more sustainable, and more efficient future for underwater energy extraction.

References and Further Reading

Shaw, M., (2020). How robotics technology is improving safety at offshore oil and gas operations. NS Energy. Available at: https://www.nsenergybusiness.com/features/offshore-oilfield-technology-robotics.

Al-Walaie, S., (2021). Emerging Robotic Technologies for Oil and Gas Operations. Journal of Petroleum Technology. Available at: https://jpt.spe.org/emerging-robotic-technologies-for-oil-and-gas-operations

Stipes, C. (2023). Autonomous Robot For Subsea Oil And Gas Pipeline Inspection Being Developed At UH. University of Houston. Available at: https://uh.edu/news-events/stories/2023/august-2023/08312023-pipeline-robot.php

Sotoodeh, K. (2021). Introduction to the subsea sector of the oil and gas industry. In the book: Subsea Valves and Actuators for the Oil and Gas Industry. https://doi.org/10.1016/B978-0-323-90605-0.00006-2

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.