Researchers from the Center for Extreme Materials Research at the Korea Institute of Science and Technology (KIST) have developed an innovative microplastic removal technology. Their solution involves a floating drone equipped with hydrophilic tooth structures that utilize surface tension to effectively skim microplastics from the water.

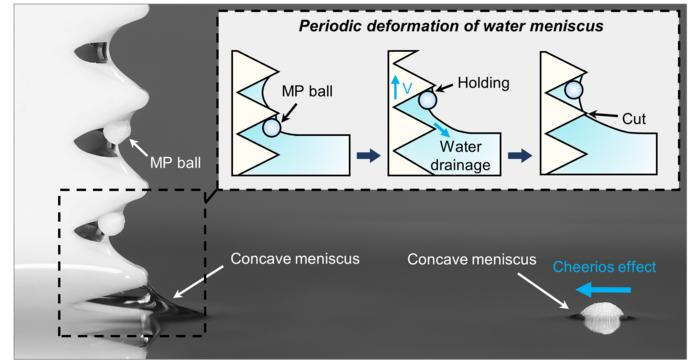

Skimming mechanism of hydrophilic teeth for MP (MP, microplastic) balls / The neighboring concave meniscus induces the Cheerios effect, causing the MP ball to naturally move toward the teeth. The schematic shows the skimming process of the MP ball with periodic deformation of the water meniscus. The skimmed MP balls are subsequently held firmly within the water-bridged teeth (by the water bridge) by capillary adhesion. Image Credit: Korea Institute of Science and Technology

Microplastics have become a significant environmental concern in recent years, with their presence detected in tap and bottled water, as well as in natural water sources like rivers, lakes, and oceans.

Traditional water treatment methods often struggle to filter out microplastics of various sizes and shapes, and these systems are prone to clogging. Moreover, effectively recovering small particles requires fine filtration, which increases pressure and decreases the efficiency of the system. These challenges are particularly evident in open bodies of water, such as lakes and oceans, where microplastic pollution is escalating.

The team's research seeks to address this growing issue.

The key innovation of this technology lies in the hydrophilic ratchet structure, which creates a water bridge between the teeth due to its affinity for water. This design maximizes the surface tension, allowing the microplastics to adhere to the teeth. This method can capture microplastics ranging from 1 micrometer (μm) to 4 millimeters, addressing the issues of size and shape variability that challenge conventional filtering systems. Additionally, the design ensures smooth operation without the risk of clogging.

The technology has demonstrated over 80 % recovery efficiency for various types of microplastics, including expanded polystyrene, polypropylene, and polyethylene. Notably, the floating drone's hydrophilic ratchet structure enables real-time removal of microplastics from large water bodies such as oceans, lakes, and rivers. The drone operates autonomously, much like a household robot vacuum cleaner, offering a versatile solution beyond the limitations of fixed filtering systems.

This technology can be applied not only to floating drones but also to stationary systems such as water treatment filters in aquaculture farms. It can also be expanded into a home water treatment filter device that individuals can use in their daily lives.

Myoung-Woon Moon, Korea Institute of Science and Technology

Journal Reference:

Cho, S., et al. (2024) Capillary Skimming of Floating Microplastics via a Water‐Bridged Ratchet. Advanced Science. doi.org/10.1002/advs.202408623.