Nov 13 2015

Screwdriving, dispensing, testing, soldering, gripping, opening and closing containers and much more: the Festo modular handling platform forms the basis for a wide variety of desktop applications. This well-matched system kit, comprising kinematics, a controller and software, saves you money and reduces your time to market – from development to programming and commissioning.

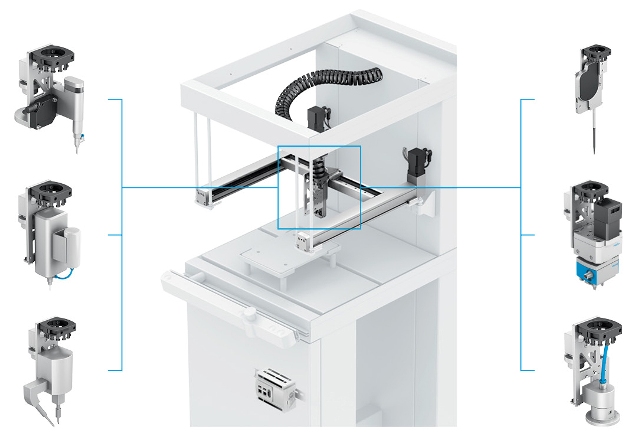

The Festo modular handling platform forms the basis for a wide variety of desktop applications, such as screwdriving, testing, dispensing, pick & place, soldering, gripping with vacuum and many more. (Photo: Festo AG & Co. KG)

The Festo modular handling platform forms the basis for a wide variety of desktop applications, such as screwdriving, testing, dispensing, pick & place, soldering, gripping with vacuum and many more. (Photo: Festo AG & Co. KG)

The modular handling platform allows precise curved travel paths to be created for transporting workpieces or tools. It is particularly suitable for electronics and light assembly as well as for laboratory automation. Machine and system builders can significantly reduce their engineering costs with these system kits. Predefined function modules from a software library and intuitive application programming with the sequencer simplify programming and commissioning.

Ready to use and reliable

This system kit from Festo forms a basic platform for a wide variety of applications. It is ready to use and can be easily integrated into the application environment of a machine builder thanks to the open interfaces. The perfectly matched components and functions of the kinematics, the controller and software guarantee operational reliability. The use of standard components ensures attractively priced solutions. Kits of this kind open up entirely new potential for savings. They enable machine and system builders to concentrate fully on their core business.

Software provides an easy way to reach the desired result

Programming and commissioning are quick and easy with the predefined function modules of the Handling Motion Lib. The following functions are possible: parameterisation as appropriate to the connected kinematics, reference travel and jogging operation for the kinematics, predefined CNC programs, point-to-point motion, U-picks, circular travel, curved travel, a defined interface for communication and host systems, file management and a message system for error handling and sequential processing. What is more, the basic sequencer with its graphical user interface (GUI) ensures that program sequences can be generated simply and reliably.

Compact and connective

Included in the system kit is a compact controller CECC-X. This allows numerous functions to be carried out in very small spaces. It contains a range of predefined interfaces to a master control system – including the OPC-UA interface for Industry 4.0.