Reviewed by Lexie CornerJun 11 2025

Researchers from the China Electric Power Research Institute and the Chinese Academy of Sciences developed a microrobot capable of manipulating tiny droplets using magnetic fields.

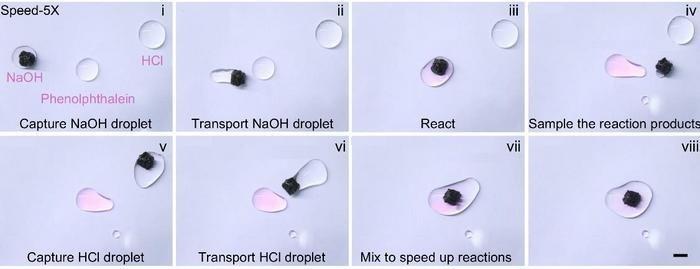

A magnetic microrobot pulls fluid droplets together, triggering a chemical reaction. Image Credit: Sun et al.

A magnetic microrobot pulls fluid droplets together, triggering a chemical reaction. Image Credit: Sun et al.

While fluid mixing is often associated with laboratory equipment like test tubes and beakers, chemical processes also occur on much smaller scales. In some industrial and medical applications, where only fractions of a milliliter are involved, a small robot can be a practical tool for fluid handling.

The researchers created the microrobot by combining sugar, a chemically stable polymer, and neodymium magnetic particles. When the sugar dissolved, it left pores in the polymer, increasing its surface area. Plasma treatment made the surface hydrophilic, allowing it to attract water and other liquids.

We aimed to create a cleaner, faster system that avoids residue, which is especially relevant for sensitive tasks like medical diagnostics or handling reactive chemicals. Ensuring chemical stability and high performance was a key priority.

Lin Gui, Study Author and Assistant Professor (UK Lecturer), King's College London

By adding magnetic particles, the team was able to control the robot using magnetic fields. The use of neodymium particles made it more responsive and efficient than existing magnetic microrobots.

Gui added, “Previous magnetic methods struggled with weak driving forces, limiting droplet size and speed. Magnetic additives also often corroded or polluted samples. Designing a robot that combines strong magnetism, chemical resistance, and rapid movement requires innovative materials and engineering.”

In experiments, the researchers used magnetic fields to guide the robot into a droplet. The surface treatment allowed the robot to pull the droplet along. At high speeds, it could split a droplet into smaller parts. At low speeds, it could merge droplets to trigger chemical reactions.

The robot moved droplets larger than a milliliter and operated at speeds 20 times faster than earlier designs. It also withstood contact with corrosive substances, such as acids, without damage.

The team sees potential applications in automating lab procedures or performing minimally invasive medical tasks. They plan to continue improving the robot’s design.

Gui concluded, “We aim to miniaturize it for handling nanoliter droplets and explore integration with sensors for tasks like targeted drug delivery or pollution cleanup.”

Journal Reference:

Sun, X. et al. (2025). Hydrophilic hard-magnetic soft robots: A new approach for precise droplet manipulation. Nanotechnology and Precision Engineering. doi.org/10.1063/5.0251223