In this interview, industry expert Ian Ross examines the evolution of mobile robots, key technological advances, design and deployment trade-offs, scaling challenges, and emerging requirements for high-payload systems in regulated industrial environments.

Can you start by explaining the difference between AGVs and AMRs to set the foundation for this discussion?

An Automated Guided Vehicle (AGV) is a floor-bound system designed for intralogistics transportation. It operates automatically and follows predefined paths, making it ideal for structured environments. AGVs are commonly used inside and outside industrial buildings to move materials efficiently.

In contrast, Autonomous Mobile Robots (AMRs) are capable of dynamically navigating around obstacles and choosing alternative paths as needed, which allows them to operate in more complex and changing environments.

However, this obstacle avoidance function in mobile robots is not always beneficial. Bypassing unpredictable obstacles often requires more space and makes the robot’s path less predictable. Additionally, it lacks precision simulation, making it difficult to calculate or estimate how many mobile robots are needed for a specific workflow. This can lead to inefficiencies and confusion for operators, especially when there is no clear route for the robot to follow, increasing adoption time and the learning curve.

At Stäubli, we prefer to use the term “mobile robot” and focus on explaining its features to avoid confusion between AGVs and AMRs.

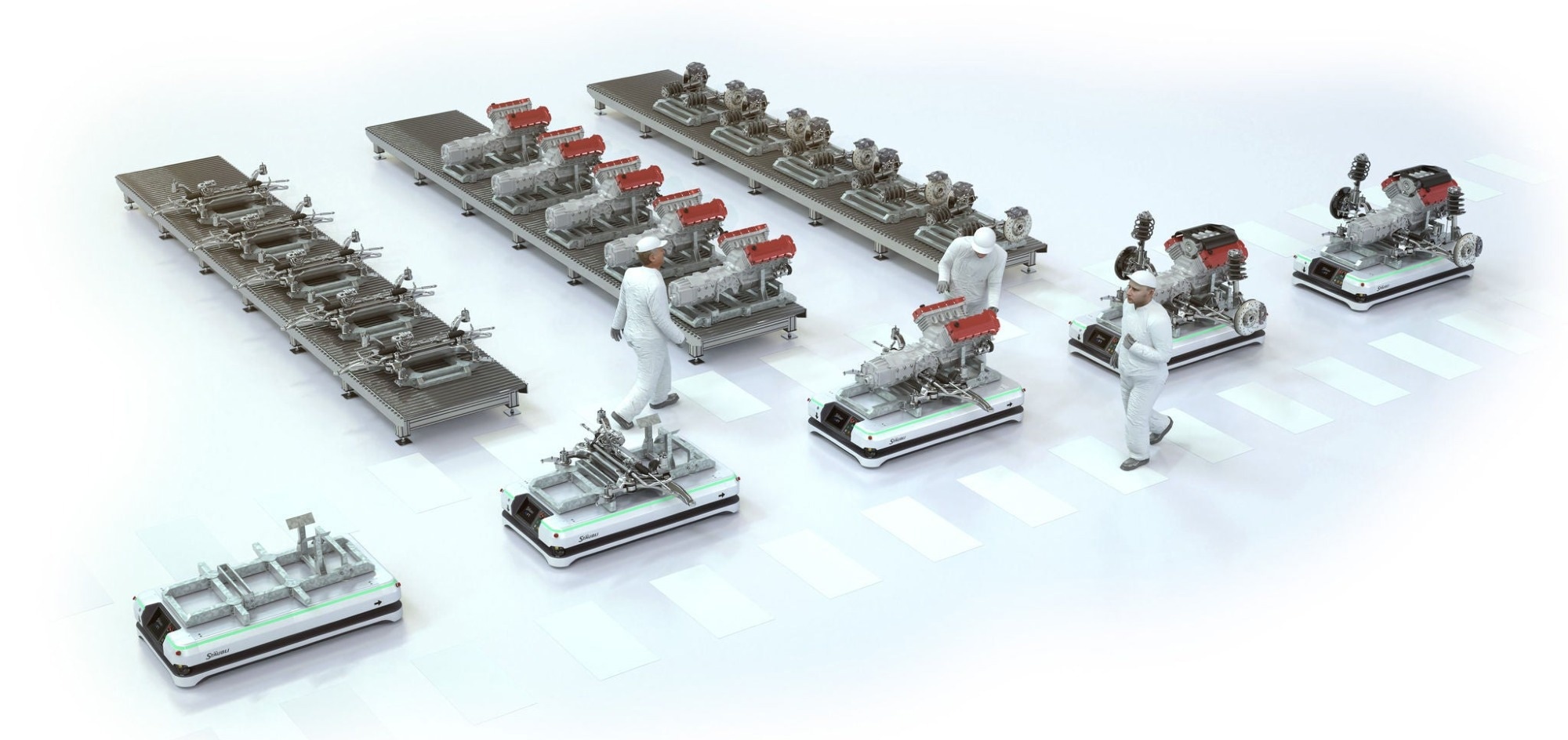

Image Credit: Stäubli Robotics

How has the role of AMRs changed in the mobile robotics industry over the past few years?

The role of AMRs has evolved dramatically, moving from niche applications to becoming a cornerstone of modern intralogistics and manufacturing strategies. Initially, AMRs were seen as experimental solutions, but today they are recognized as essential tools for addressing labor shortages, improving safety, and enabling Industry 4.0 digitalization. Their ability to generate operational data has made them a key enabler for smart factories.

Demand is growing fastest in sectors where flexibility and precision are critical. The automotive industry, particularly electric vehicle (EV) production, has emerged as a technology leader. EV manufacturing requires agile material handling and dynamic workflows, making AMRs indispensable for transporting components and supporting just-in-time processes.

The pharmaceutical sector is also experiencing significant growth in AMR adoption, driven by new Good Manufacturing Practice (GMP) Annex 1 regulations. These regulations mandate stringent contamination control in cleanrooms, where AMRs provide a contamination-free alternative to manual handling, ensuring compliance and improving efficiency.

In aerospace and defense (A&D), AMRs are being deployed for dynamic tooling and high-payload applications, particularly for loads ranging from 1.5 to 6 tons. This sector is also influenced by innovations such as electric vertical take-off and landing (eVTOL) aircraft development, which demands clean, efficient, and expedited material flow processes. AMRs are increasingly used to move large components and tooling systems in environments where precision and safety are paramount.

These examples illustrate how AMRs have transitioned from being optional enhancements to becoming strategic assets across industries that prioritize automation, safety, and scalability.

What technological advancements have contributed most to the growing capabilities of AMRs?

The rapid evolution of AMRs has been driven by advancements in sensing, software, and artificial intelligence. Modern AMRs now rely on a suite of laser safety-rated sensors, high-resolution cameras, and radar systems. These sensors enable precise environmental mapping, robust obstacle detection, and safe navigation even in dynamic and unpredictable settings.

Laser scanners provide accurate distance measurements and 360-degree awareness, while cameras and radar offer layers of redundancy, allowing robots to interpret complex scenes and distinguish between static objects and moving people. This multi-sensor fusion is essential for reliable operation in industrial environments and public spaces. Additionally, improvements in 5G connectivity have reduced interference issues common with traditional wireless channels, further enhancing reliability.

In your view, what distinguishes a next-generation AMR from earlier designs?

Next-generation AMRs represent a significant evolution from earlier, highly customized solutions. Historically, mobile robotics projects were tailored to meet specific customer requirements, resulting in unique designs for each application. While this approach allowed flexibility, it often led to longer deployment times, higher costs, and challenges in scaling operations across different sites.

Today, standardization and scalability are key. It is increasingly common for greenfield environments to design processes around AMRs rather than adapting existing workflows to accommodate them.

Image Credit: Stäubli Robotics

How are companies approaching interoperability and fleet management as AMR deployments scale?

As AMR deployments grow in scale and complexity, companies are prioritizing interoperability and advanced fleet management to ensure operational efficiency and flexibility.

Modern fleet management platforms have evolved to meet these demands by providing centralized control over all robots within a facility, regardless of manufacturer. These systems enable real-time monitoring, intelligent task assignment, traffic coordination, and dynamic re-routing based on live operational data.

Advanced analytics and reporting tools further enhance performance by identifying bottlenecks, predicting maintenance needs, and ensuring compliance with safety standards. The introduction of standardized communication protocols - most notably VDA 5050 - has been a game-changer for interoperability. This standard allows mixed-brand fleets to communicate seamlessly with fleet management systems, eliminating vendor lock-in and enabling manufacturers to scale operations without costly custom integration. By leveraging these technologies, companies are transforming mobile robotics from isolated solutions into fully connected ecosystems that deliver flexibility and efficiency on the production floor.

What are the main obstacles customers encounter when scaling AMR deployments beyond the initial pilot phase, especially regarding interoperability and cybersecurity?

Customers often encounter obstacles related to technology know-how and its limitations, as well as acceptance by operators on the shop floor. Interoperability and cybersecurity become significant concerns at this stage.

Integrating AMRs into existing workflows requires rethinking processes, with a focus on material flow before introducing AGVs. Engaging operators and ensuring their ownership of the process is critical. Keeping solutions simple helps minimize complexity and facilitates adoption.

How do you see AMRs evolving over the next five years in terms of intelligence, autonomy, and application scope?

AMRs are expected to undergo significant evolution over the next five years in terms of intelligence, autonomy, and application scope. Key trends in software, sensors, and AI, such as seamless integration with other mobile robot brands and manual vehicles, enhanced cybersecurity, and predictive maintenance, will have the greatest impact on the future of mobile robotics.

The next major leap will likely be defined by the ability to work together as a whole system, integrating seamlessly with other mobile robot brands and manual vehicles through standard communication interfaces.

What unique capabilities or qualities make Stäubli stand out in the mobile robotics market?

Stäubli Mobile Robots stand out due to high-end mechatronics technology, including a patented drive unit, and unique expertise in high-payload applications and sensitive environments such as pharmaceuticals (e.g., with Sterimove). With over 20 years of experience developing and implementing mobile robotics projects worldwide, Stäubli is committed to investing heavily in mobile robotics capabilities in the coming years. As a 125-year-old family-owned company, Stäubli is dedicated to long-term success and innovation.

About Ian Ross

Ian Ross holds a BE in Mechanical Engineering from the University of South Carolina. He is currently a Lead Systems and Applications Engineer at STÄUBLI, serving as a technical authority for mobile robotics and high-payload systems in North America, with a focus on applications engineering and custom solutions.

This information has been sourced, reviewed and adapted from materials provided by Stäubli Robotics.

For more information on this source, please visit Stäubli Robotics.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.